- Contact:

- Tel:+8613868770229

- Phone:+8613868770229

- Mail:jiangku@cnjkdq.cn

- Product Details

1 Scope

This standard specifies the product model and specifications, technical requirements, test methods, inspection rules, identification, packaging, transportation, and storage of railway signal combination cabinets.

This standard is applicable to railway signal combination cabinets for the control circuits of centralized electrical relays in stations.

2. Normative references

The following documents are indispensable for the application of this document. For dated reference documents, only the dated version applies to this document. For undated reference documents, the latest version (including all amendments) is applicable to this document.

GB/T 191 Packaging, storage and transportation pictorial signs

GB/T 2828.1 Sampling inspection procedure by attributes Part 1: Batch inspection sampling plan retrieved by acceptance quality limit (AQL)

GB/T 2829 Periodic Inspection Attribute Sampling Procedure and Table (Applicable to the inspection of process stability)

GB/T 5023-2008 (all parts) PVC insulated cables with rated voltages of 450/750V and below

GB/T 11253-2007 Carbon structural steel cold-rolled sheet and steel strip

GB/T 19666-2005 Flame-retardant and fire-resistant wire and cable general rules

SJ 20910-2004 General Specification for Powder Electrostatic Coating

TB 1447-1982 Insulation resistance of signal products

TB 1448-1982 Insulation withstand voltage of communication signal products

3. Product model and specifications

3.1 The model of the cabinet product and its meaning

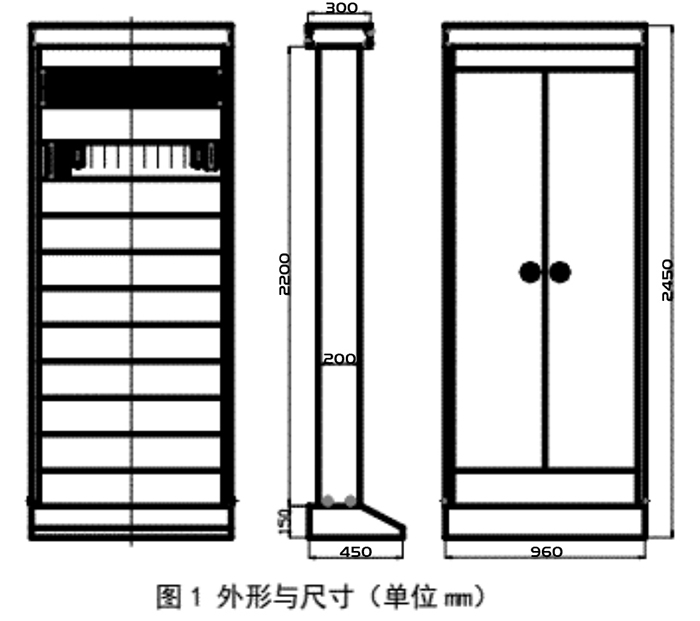

3.2 Shape and size

The appearance and dimensions of the combined cabinet are shown in Figure 1. The unit in the figure is mm.

4 Technical requirements

4.1 Working environment

The combined cabinet should work reliably under the following environmental conditions:

a) Atmospheric pressure is not lower than 74.8kPa (altitude not exceeding 2500m);

b) The ambient air temperature is -40℃~50℃;

c) The relative humidity of the air is not more than 85% (25℃);

d) There is no harmful gas and conductive dust that can corrode metals, damage insulation, and cause explosion hazards.

4.2 Drawings and technical documents

The combined cabinet shall meet the technical requirements of this standard and be manufactured in accordance with the drawings and technical documents approved by the prescribed procedures.

4.3 Parts

4.3.1 All parts and components of the combined cabinet must be inspected and qualified, and the standard parts and external components must meet the relevant technical standards before they can be assembled.

4.3.2 The surface of the electroplated parts should be smooth, without spots, bumps and unplated places, and there should be no burn marks on the edges and corners.

4.3.3 The non-metallic surface should be smooth, shiny, free of cracks, bubbles, lack of material, looseness, and obvious deformation.

4.4 Insulation withstand voltage

When the atmospheric pressure is not less than 84kPa (the altitude is not more than 1000m), the combination and combination cabinet should be able to withstand the AC sine wave 50Hz, the voltage effective value of 1000V, and the withstand voltage test lasting 1min without breakdown or flashover.

4.5 Insulation resistance

4.5.1 When the temperature is 10℃~35℃ and the relative humidity is 50%~80%, the insulation resistance of the combination and combination cabinet should not be less than 20MΩ.

4.5.2 The moisture insulation resistance of various terminal boards in an environment with a temperature of 20℃±5℃ and a relative humidity of 95%±3℃ should be no less than 0.5MΩ after being placed for 72 hours.

4.6 Combination cabinet composition

4.6.1 The combined cabinet is constructed by connecting and assembling the components. The connection should be firm and tidy. The connection between the components should be smooth. The gap between the door and the cabinet should be even up and down, left and right, and the door should open and close flexibly.

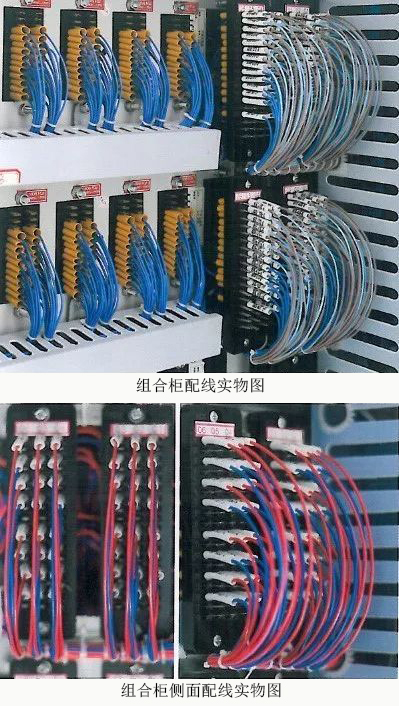

4.6.2 The combined cabinet should contain 11 combined layers, generally including 1 zero layer and 10 combinations. The zero layer is generally located on the top layer. The other layers can be installed with combination, other equipment or closed according to the design requirements.

4.6.3 The combination cabinet shall be equipped with plastic wiring troughs for wiring between each combination.

4.6.4 The upper part of the combined cabinet should have a wiring trough for placing the wiring cables. The cross-sectional size of the wiring trough should generally be 300mm×100mm. The bottom of the wiring trough should have a hole that communicates with the cabinet body for easy wiring.

4.7 Combination

4.7.1 The combination wiring connection should meet the requirements of the design drawings. Each combination should pass the continuity test and be affixed with the certificate before it can be installed in the combination cabinet.

4.7.2 The cable used in the combined wiring shall meet the requirements of GB/T 5023-2008, the model is 60227 IEC 06, and meet the relevant requirements of the flame-retardant category C in GB/T 19666-2005, and the general cross-section shall not be less than 0.379mm2, or According to design requirements.

4.7.3 The length of the combined wiring should have a margin of 25mm ± 5mm, and there should be no damage to the joint and the insulation layer in the middle of each connection.

4.7.4 Combination wiring welding should be through welding. The solder joints should be bright, full and firm, without false or false soldering. The solder joints should be covered with insulating sleeves, and the plug-in connection should not be stuck on the insulating layer. .

4.7.5 The various socket bottom plates and accessories used in the combination shall meet the relevant design requirements, and the installation of the socket bottom plates shall be parallel to each other and perpendicular to the base.

4.7.6 The combination should be equipped with a plastic wire trough, and the wiring should be led into the plastic wire trough.

4.8 Combination frame and cabinet processing

4.8.1 The main sheet metal parts of the combined cabinet shall be processed by steel plates or steel strips that comply with the grade Q235 in GB/T 11253-2007.

4.8.2 The processed cuts should be flat and smooth, without burrs, and the welding should be firm and beautiful, and there should be no false or false welding.

4.8.3 The surface of the main parts of the combined cabinet shall be treated with powder electrostatic coating, and shall comply with the relevant regulations of SJ 20910-2004.

4.8.4 The color of the surface coating should generally be beige, and the PANTONE color code should be 428C.

4.8.5 The surface coating layer should be evenly coated, the color should be consistent, and there should be no defects such as bubbles, shedding, missing coating, and dirt.

5. Test method

5.1 Insulation test

5.1.1 The insulation withstand voltage of the combined cabinet shall be implemented in accordance with the relevant regulations of TB 1448-1982, and shall comply with the regulations of 4.4.

5.1.2 The insulation resistance of the combined cabinet shall be implemented in accordance with the relevant regulations of TB 1447-1982, and shall comply with the regulations of 4.5.

5.2 Continuity test

5.2.1 Each combination shall be subjected to a continuity test.

5.2.2 Conventional test method Put the multimeter in the resistance file, compare the combination design drawing, touch the two meter rods of the multimeter respectively to the two points that should be connected as specified in the figure, and observe whether the multimeter is connected (or in other ways such as sound indicating connection). through). The test of the remaining contacts can be deduced by analogy.

5.2.3 Test bench test method When there is more than one combination of the same type, the subsequent combination can be tested on a test bench, and the steps are as follows:

a) First, test the first combination of the same type according to 5.2.2 to confirm that it is qualified;

b) Place the combination on the test bench, insert a test plug into each socket board, start the test program collection function, collect the connection information of the qualified combination into the test program and save, then remove the combination;

c) Place the combination to be tested on the test bench, insert a test plug into each socket board, and start the test program test function. The program uses the connection information obtained in step b) above as the comparison standard for testing. If the two are consistent, The tested combination is qualified.

6 Inspection rules

6.1 Factory inspection

6.1.1 Each combined cabinet must be inspected and qualified by the manufacturer and accompanied by a product certificate before it can leave the factory.

6.1.2 The factory inspection shall be carried out in accordance with 4.3, 4.4, 4.5.1, 4.6, 4.7, and 4.8.5.

6.2 User request re-inspection

6.2.1 The user re-inspection items are the same as the factory inspection, but the test voltage during the insulation withstand voltage re-inspection should be 80% of the original test voltage value.

6.2.2 The numbered sampling inspection shall be used in the re-inspection, which shall be carried out in accordance with the regulations of GB/T 2828.1 and shall meet the following regulations:

a) IL=Ⅱ;

b) Reception quality limit: AQL=2.5;

c) Strictness: normal inspection sampling plan;

d) Type of sampling method: one-time sampling plan.

6.2.3 Test unqualified batch: the manufacturer is allowed to take measures for the unqualified products in the batch of products, and the re-inspection should be carried out according to the stricter inspection plan. If the batch is still unqualified, the whole batch of products will be judged as unqualified.

6.3 Type test

6.3.1 Type test should be carried out under the following conditions:

a) Trial type appraisal of new products or re-factory production;

b) After formal production, if there are major changes in structure, materials, and processes that affect product performance;

c) When production is stopped for more than three years and production is resumed;

d) During normal production, once every three to five years;

e) When there is a big difference between the result of the factory inspection and the result of the last type test;

f) When the quality supervision agency proposes to carry out the type test request.

6.3.2 The content of the type test shall include all the contents of this standard.

6.3.3 The products used for type testing shall be randomly selected from the batches that have passed the factory inspection.

6.3.4 The type test shall be carried out in accordance with the relevant regulations of GB/T 2829, and shall meet the following regulations:

a) Discrimination level: DL=Ⅱ;

b) Unqualified quality level: RQL=40;

c) Sampling plan type: one-time sampling plan;

d) Discriminant array: qualified judgment number Ac=0 The number of unqualified judgments Re=1.

6.3.5 If the number of unqualified products is greater than or equal to the number of unqualified judgments, the type test is unqualified, and the manufacturer shall take measures to solve the existing problems until the type test is qualified.

6.3.6 The samples that have passed the type test shall not be delivered as qualified products.

7 Identification, packaging, transportation and storage

7.1 Identification

Product packaging and storage pictorial signs shall be implemented in accordance with the provisions of GB/T 191. Each combined cabinet shall be provided with a product label, which includes:

a) Product model and name;

b) Factory number or cabinet number;

c) Date of manufacture;

d) The name of the manufacturer.

7.2 Packaging

Combination cabinets should be packaged, and the outer packaging should have the product model, name, quantity, name and address of the receiving and shipping unit, and mark "upward", "fragile items", "fear of rain" and other signs on the outer packaging.

7.3 Transportation

The combined cabinet should be protected from mechanical damage, strong vibration, collision and direct rain (snow) during transportation.

7.4 Storage

The combined cabinet should be stored in a warehouse with good ventilation, no corrosive and harmful gases around it, with a temperature of -25℃~40℃, and a relative humidity of not more than 85℃.

Comments Box